Threshed seed contains all kinds of trash. This trash can be vegetative, such as chaff, straw, empty grains and foreign seed, as well as mineral materials, such as earth and stones. Seed should be as soon as possible after harvesting and certainly before storage.

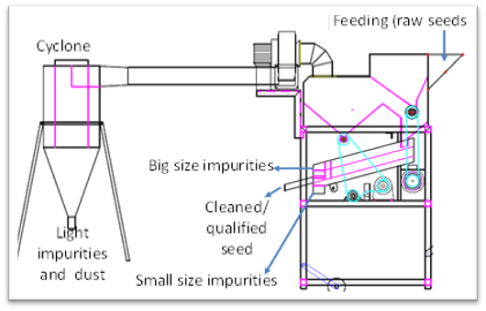

Mechanical winnowers that incorporate a fan and several superimposed reciprocating sieves or screens are now used in many countries. These can be manually powered or motorized and have capacities from 100 kg/h to 2–3 t/hr. Where combine harvesters are used, there is a trend towards using large-capacity centralized seed cleaners. These are normally equipped with a series of vibrating sieves and are capable of 10–30 t/hr.

Seed cleaners are typically designed to separate grains from other materials based on specific weights and dimensions of the grains. A seed grader separates seeds into different fractions of seeds with different dimensions and weights. A simple seed cleaner often has two sieves for separating large and small impurities. A drum-type cleaner has rotating drum-sieves instead of oscillating-sieves. Drum cleaners usually have higher capacity but lower cleaning efficiency than the oscillating-sieve cleaners.

The figure above shows the schematic diagram of a seed cleaner combining a blower for dust and light impurity aspiration and the oscillating sieves for grading seeds as well as cleaning weed grains based on the specific weight differences. Seed cleaning and grading are very important to ensure better seeding operations (e.g., using drum seeders, seed sprayers, etc.), minimize seed rate and reduce weeds, and increase grain yield and quality.